SOLUTIONS FOR VACCINE FREEZERSSMART Case Study | Remotely Monitoring Medical Refrigerators

Public and private medical organizations across the nation have been reaching out to SMART to help further their efforts to fight the coronavirus. After helping to network dozens of mobile and pop-up vaccination facilities, a new challenge arose.

Many vaccines were going bad before medical technicians could use them. Facilities needed a solution to remotely monitor fixed and portable refrigeration units. As before, SMART was eager to help. |

Challenges Faced

Preventing Vaccine Spoilage

As each vaccine manufacturer has different requirements and shelf lives, health departments need to track which refrigeration units contain which vaccine to ensure they maintain the specific temperature levels manufactures require. Some medical organizations have lost doses resulting from the improper mixing of manufacturers within the same refrigeration unit. Others lost doses to unreported temporary or intermittent power outages. And still others lost supplies due to instances of simple human error (like forgetting to close the fridge).

Our client wanted to prevent these issues from occurring during their own vaccine deployment efforts.

Our client wanted to prevent these issues from occurring during their own vaccine deployment efforts.

Case OverviewManaging Vaccine Storage

Proper refrigeration posed one of the largest challenges county and state health agencies have faced in deploying vaccinations. Vials containing the COVID-19 vaccine need to be stored at very specific temperatures based on the original manufacturer. For example, the Moderna Vaccine needs to stay in freezers between -25°C and -15°C. Once ready for use, they can be moved to refrigerators and stored between 2°C and 8°C (36°F and 46°F) for up to 30 days, and then must be discarded. Once removed from refrigeration, technicians have twelve hours to use them or dispose of them (following Moderna guidelines).

|

Solutions Deployed

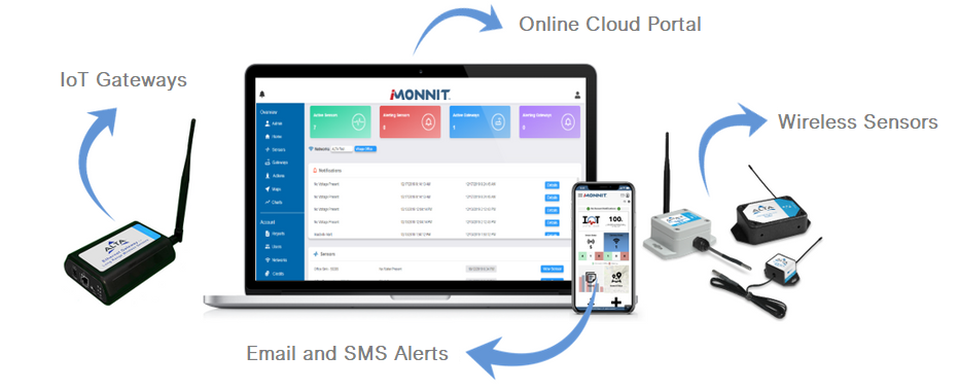

After researching the challenges associated with proper vaccine storage, SMART worked out a solution to prevent and reduce the loss of vital vaccines by combining remote sensors and cellular routers to create a single all-in-one solution for their remote refrigeration monitoring needs.

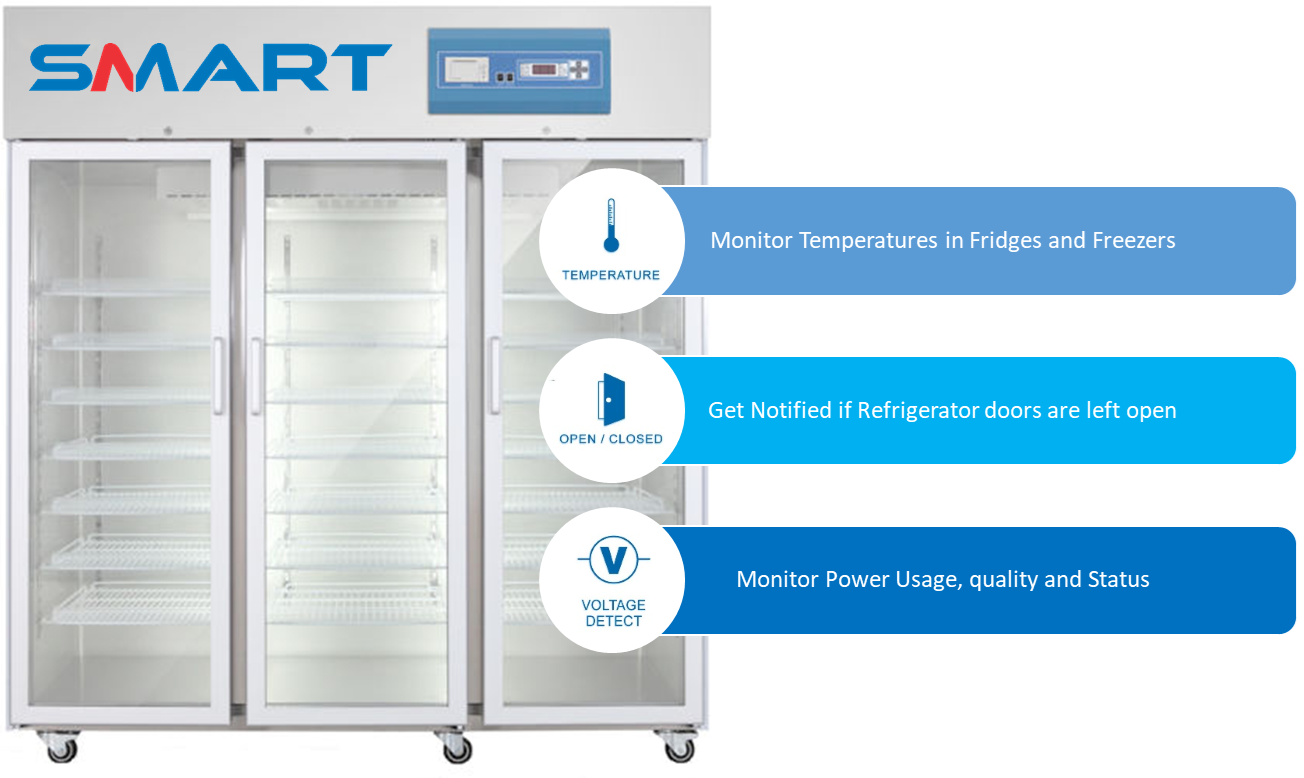

Wireless Sensors

SMART has access to manufactures that produce dozens of wireless monitoring devices for a variety of specific uses. For applications in the medical industry, and specifically for the use case featured here, the most relevant sensors available for this project are for temperature, power, and activity monitoring. Accurate within 0.5°C, the temperature sensors we helped procure are the ideal solution for ensuring vaccine refrigeration units are maintaining manufacture recommended temp levels.

We can recommend power detection sensors available in both AC and DC models that simply detect the presence or absence of electrical currents to your medical assets. Receive instant notifications when power outages occur so that vaccine fridges can immediately be switched to backup power sources or vials relocated to functioning units. Another useful device for this application are activity sensors. With these in place you can receive notifications when freezer doors are opened or closed, and also if they remain open for longer than desirable based on intervals you can set.

Results Delivered

With all sensors and routers in place healthcare professionals can remotely monitor every refrigeration unit under their control in both permanent and temporary locations from a single desktop in their offices or smart device on the road. With Monnit's CFR21 Part 11 Cloud based software services, they can register, configure, and update their routers over-the-air. And with sensor software they can remotely manage each sensor in the same way. Today, our healthcare customers can receive instant notifications whenever a unit door is opened and closed, when a door stays open for too long, if a loss in power occurs, and if temperatures fluctuate outside of predefined limits.